Première ! L'Université de Tel-Aviv imprime un cœur vivant en 3D à partir de cellules humaines et pourra imprimer n'importe quel greffon

[:fr]

Les chercheurs du laboratoire du Prof. Tal Dvir de l’Université de Tel-Aviv ont réussi, pour la première fois au monde, à résoudre un défi majeur de la médecine moderne: utiliser une imprimante 3D pour imprimer un cœur vivant à partir de tissus prélevés sur un patient. D’après eux, la méthode ouvre la voie à la médecine du futur, et dans dix ans il sera possible d’imprimer pour chaque patient l’organe dont il a besoin à partir de tissus prélevés sur son corps, et il ne sera plus nécessaire d’attendre les greffes d’organes avec leurs risques de rejet.

Ces travaux novateurs ont été réalisés par le doctorant Nadav Nur et le Dr. Assaf Shapira dans le laboratoire de Tal Dvir, affilié à trois unités de recherche de l’Université de Tel-Aviv : l’Ecole de biologie cellulaire moléculaire et de biotechnologie de la Faculté des sciences de la vie, le Département de génie des matériaux de la Faculté d’ingénierie et le Centre de recherche pour la biotechnologie régénérative.

« Depuis l’invention de la technologie d’impression tridimensionnelle, les chercheurs du monde entier tentent de l’utiliser pour imprimer, entre autres, des tissus et des organes destinés à la transplantation. Nous avons développé une nouvelle technologie qui résout un bon nombre des difficultés » , explique le Prof. Dvir.

Pour réaliser cette étude, les chercheurs ont utilisé des tissus adipeux prélevés sur un patient et y ont séparé les cellules graisseuses du collagène extracellulaire qui soutient le tissu. Puis, par un processus avancé d’ingénierie génétique, ils ont transformé ces cellules en cellules souches, à partir desquelles ils ont fabriqué des cellules du muscle cardiaque (myocarde) et des cellules vasculaires.

En parallèle, ils ont créé à partir du collagène une sorte ‘d’encre’ pour permettre l’impression. Ensuite, ils ont mélangé tous ces matériaux et alimenté avec ce mélange une imprimante en 3D, qui a imprimé conformément aux instructions de l’ordinateur, en fonction des images d’un cœur humain obtenues par IRM et par tomographie.

Un cœur de n’importe quelle taille, sans réaction immunitaire

Le cœur ainsi imprimé est constitué de très jeunes cellules, qui sont déjà capables de se contracter et présentent les propriétés des cellules cardiaques. Les chercheurs travaillent à présent à la maturation de ce cœur dans un environnement spécifique (bio-réacteur) jusqu’à ce que les cellules deviennent adultes, capables de communiquer entre elles par des signaux électriques et de fonctionner avec une efficacité maximale. Les chercheurs espèrent qu’au cours de l’année à venir, des cœurs imprimés de ce type seront implantés chez les animaux afin d’en tester le fonctionnement.

Le cœur ainsi imprimé est constitué de très jeunes cellules, qui sont déjà capables de se contracter et présentent les propriétés des cellules cardiaques. Les chercheurs travaillent à présent à la maturation de ce cœur dans un environnement spécifique (bio-réacteur) jusqu’à ce que les cellules deviennent adultes, capables de communiquer entre elles par des signaux électriques et de fonctionner avec une efficacité maximale. Les chercheurs espèrent qu’au cours de l’année à venir, des cœurs imprimés de ce type seront implantés chez les animaux afin d’en tester le fonctionnement.

« La méthode que nous avons développée nous permet d’imprimer un cœur de n’importe quelle taille. De plus, dans la mesure où ce cœur imprimé est produit à partir des propres tissus du patient, son système immunitaire ne le rejettera pas, comme cela arrive fréquemment pour les greffes d’organes actuelles. Enfin, cette méthode convient pour tous les organes susceptibles d’être greffés, et nous pensons qu’elle ouvre la voie à des technologies futures qui permettront de remplacer totalement les dons d’organes. Lorsqu’un patient aura besoin d’une transplantation, on prélèvera des tissus sur son corps, à partir desquels on pourra imprimer un organe personnalisé, adapté au patient par sa taille et ses caractéristiques et qui pourra être implanté dans son organisme », conclut le Prof. Dvir.

Auteur : Sivan Cohen-Wiesenfeld, PhD, Rédac’chef de la newsletter des Amis français de l’Université de Tel Aviv

Publication dans Advanced Science, le 15 avril 2019

[:en]

In a major medical breakthrough, Tel Aviv University researchers have « printed » the world’s first 3D vascularised engineered heart using a patient’s own cells and biological materials. Their findings were published on April 15 in a study in Advanced Science.

Until now, scientists in regenerative medicine — a field positioned at the crossroads of biology and technology — have been successful in printing only simple tissues without blood vessels.

« This is the first time anyone anywhere has successfully engineered and printed an entire heart replete with cells, blood vessels, ventricles and chambers, » says Prof. Tal Dvir of TAU’s School of Molecular Cell Biology and Biotechnology, Department of Materials Science and Engineering, Center for Nanoscience and Nanotechnology and Sagol Center for Regenerative Biotechnology, who led the research for the study.

Heart disease is the leading cause of death among both men and women in the United States. Heart transplantation is currently the only treatment available to patients with end-stage heart failure. Given the dire shortage of heart donors, the need to develop new approaches to regenerate the diseased heart is urgent.

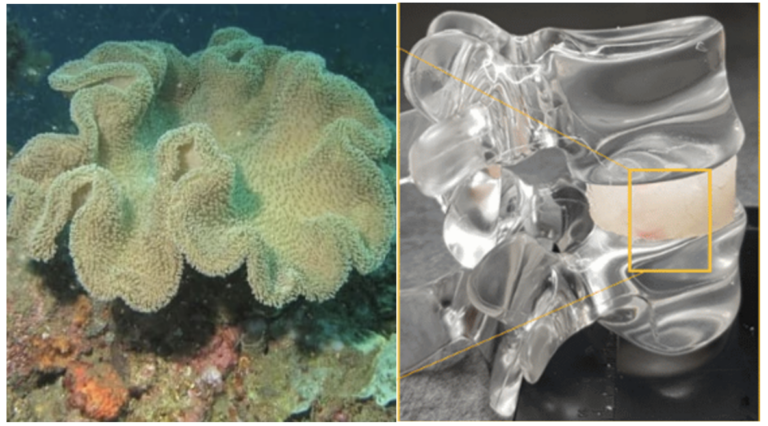

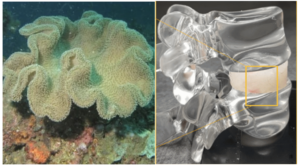

« This heart is made from human cells and patient-specific biological materials. In our process these materials serve as the bioinks, substances made of sugars and proteins that can be used for 3D printing of complex tissue models, » Prof. Dvir says. « People have managed to 3D-print the structure of a heart in the past, but not with cells or with blood vessels. Our results demonstrate the potential of our approach for engineering personalized tissue and organ replacement in the future. »

Research for the study was conducted jointly by Prof. Dvir, Dr. Assaf Shapira of TAU’s Faculty of Life Sciences and Nadav Moor, a doctoral student in Prof. Dvir’s lab.

« At this stage, our 3D heart is small, the size of a rabbit’s heart, » explains Prof. Dvir. « But larger human hearts require the same technology. »

For the research, a biopsy of fatty tissue was taken from patients. The cellular and a-cellular materials of the tissue were then separated. While the cells were reprogrammed to become pluripotent stem cells, the extracellular matrix (ECM), a three-dimensional network of extracellular macromolecules such as collagen and glycoproteins, were processed into a personalized hydrogel that served as the printing « ink. »

After being mixed with the hydrogel, the cells were efficiently differentiated to cardiac or endothelial cells to create patient-specific, immune-compatible cardiac patches with blood vessels and, subsequently, an entire heart.

According to Prof. Dvir, the use of « native » patient-specific materials is crucial to successfully engineering tissues and organs.

« The biocompatibility of engineered materials is crucial to eliminating the risk of implant rejection, which jeopardizes the success of such treatments, » Prof. Dvir says. « Ideally, the biomaterial should possess the same biochemical, mechanical and topographical properties of the patient’s own tissues. Here, we can report a simple approach to 3D-printed thick, vascularized and perfusable cardiac tissues that completely match the immunological, cellular, biochemical and anatomical properties of the patient. »

The researchers are now planning on culturing the printed hearts in the lab and « teaching them to behave » like hearts, Prof. Dvir says. They then plan to transplant the 3D-printed heart in animal models.

« We need to develop the printed heart further, » he concludes. « The cells need to form a pumping ability; they can currently contract, but we need them to work together. Our hope is that we will succeed and prove our method’s efficacy and usefulness.

« Maybe, in ten years, there will be organ printers in the finest hospitals around the world, and these procedures will be conducted routinely. »

[:]