China chooses Netafim to conserve water and increase water and fertilizer and to use efficiency and optimize tuber yields

China is the world’s largest potato producer, accounting for 22% of the global production. With increased potato production and domestic consumption, together with a gradual transition towards a market economy, China has significantly expanded its trade of potatoes and potato products in the past two decades.

Guyuan region in Hebei Province, central China, is dubbed as China’s No. 1 potato production base and is characterized by arid climate and little access to traffic. 89% percent of its 1.5 million residents are farmers out of which some 116,000 are living in absolute poverty.

Potato is planted here on 0.1 million ha with an output of 2 million tons. Guyuan presently has more than 2,000 potato processing companies, a number of wholesale markets and a potato shipping association to ensure timely delivery of fresh potatoes to 17 provinces, including Hong Kong and Macao as well as Taiwan and some European countries. By 2010, the Guyuan aims to increase its potato acreage and output to 0.2 million hectares and 4.5 million tons, respectively.

In 2008, 60% of China’s farmlands are arid and farmers will earn a higher profit from growing potatoes than from wheat, corn, paddy rice and beans, according to Mr. Qu Dongyu, Director of the China Potato Committee.

Therefore, new innovative sustainable technologies are needed not only for raising and sustaining the potato productivity per hectare but also for producing quality tubers using scarce and expensive resources such as water and fertilizer in order to meet both domestic demand (consumption per capita 32 kg) and processing industry needs and to be more competitive in the market.

Situation

Food and agro-industrial crop

Water scarcity

Inefficient use of water

Sandy loam soils

Leaching of nutrients

Low water and fertilizer use efficiency

Low tuber yields with lower quality

Why drip is needed?

The economic importance of potato in meeting food security and agro-industry demand. To conserve water, increase water and fertilizer use efficiency and optimize tuber yields.

Agro-industry name

Frito-Lay China

Farm details

Location: Frito-Lay Seed Potato Farm, Guyuan (36° 0′ 1″ N-latitude, 106° 28′ 0″ E-longitude), Hebei Province (180 Km south west of Beijing), China

Crop variety: Atlantic

Crop spacing: Row to row – 0.9 m and plant to plant – 0.15 m

Plant density: 74,074 plants/ha

Crop season: Sowing May 2006

Climate: Dry sub-humid climate, frost free

Rainfall: 521 mm/year

Reference crop evapotranspiration – 831 mm/year

Soil physical properties: Sandy

Soil pH: 6 to 7.5

Bulk density: 1.6 g/cm3

Water table: Below 6 m

Soil chemical properties: N (30 mg/kg), medium in P2O5 (6 mg/kg) and high in K2O (72 mg/kg)

Water source: Bore well

Power source: Electric pump

Agro-solution: What has been done?

Subsurface drip irrigation system (SDI):

Head control unit, main and sub-main pipes besides Super Typhoon dripline 16 mm diameter, with a lateral spacing of 0.9 m, emitter spacing of 0.3 m and emitter flow rate 1.1 Litres/hour. Each crop row was irrigated with one dripline installed 5 cm below the soil. Year of drip system installation: 2006

Agronomic and technical support:

Crop water requirement and irrigation scheduling: Depth and frequency of water application; water quality consideration and measurement of applied water.

Fertigation scheduling: Soil and water analysis, estimation of nutrient dose, selection of fertilizers and their compatibility, application skill via drip system, and foliar diagnosis for nutrient deficiencies.

System operation and maintenance: Pressure reading, valves operation, measurement of applied water. Cleaning of filters, fertilizer tank, acid treatment, chlorination, etc.

Training and capacity building: Soil water plant relationships, drip irrigation and fertigation principles, benefits, limitations and utility; water quality and herbicide usage.

Results

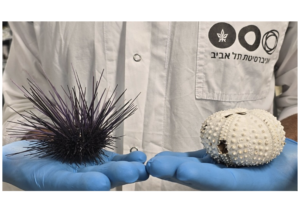

Improved tuber yield: Conventional centre pivot sprinkler irrigation – 42.0 tons/ha and with subsurface drip yield has increased by 16% (48.6 tons/ha).

Improved tuber quality: Reduction in sucrose and dextrose content by 45.8% and 136% in comparison to centre pivot sprinkler irrigation. Tuber composition favored by chips potato processing units.

Water requirement and saving: Conventional centre pivot sprinkler irrigation – 2400 m3/ha and with subsurface drip – 145 m3/ha. The water saving by using drip over centre pivot sprinkler is 40% or 950 m3/year/ha. As an illustration, the saved water can irrigate 0.65 ha.

Economic indices: Higher net returns by subsurface drip (918 US$/ha) in comparison to centre pivot sprinkler irrigation.

Additional benefits: Uniform tuber size and higher proportion of A-grade tubers, improvement in fertilizer use efficiency, management flexibility, less weed growth, and uniform irrigation of potato on undulated terrains.

Impact

Drip irrigation of potato in China is a feasible eco-technological and economically viable technology.

Use of scarce water resources, in a sustainable way, in potato cultivation to spread over a larger area.

Higher productivity, quality tubers, food security and increased income to farmers.

Farmers and processing units are willing to expand the drip irrigation to the remaining potato areas.

Potato best management practices: Subsurface drip irrigation (SDI) and fertigation scheduling.

Grow More: 16% tuber yield

With Less: 40% water saving